Mashhor Offshore Painting Services (MOPS)

Mashhor Offshore Painting Services (MOPS) is a division of Mashhor group of companies located in Kuala Belait, 15km away from its headquarters in Seria. Established in 2006, MOPS has quickly developed a superior reputation in the Bruneian market due to its meaningful customer service, qualified teams and vast experience in Blasting & Painting activities for Brunei’s offshore hydrocarbon industrial facilities.

MOPS initially started as a joint-venture with international companies who were mainly responsible for projects related to offshore painting in the 1980s. Eventually, the Company acquired the technology and skills to operate independently. In 2006, we received the honor of being the first fully owned local Bumiputra Company to have received a major offshore painting contract by Brunei Shell Petroleum. At present, MOPS operates on live offshore platforms as opposed to its previous activities on shut-down platforms.

It is within the company’s interest to train Bruneian locals to be fully reliant in the skilled career paths that are offered within our firm, through the support of our qualified and highly experienced teams with extensive knowledge of the industry.

Since its establishment, the company’s expertise, commitment to service and local know-how has scaled new heights in terms of production, local business development, HSE and quality and aims to achieve greater heights in every aspect of the business.

OUR SERVICES

- Offshore Blasting & Painting

- Offshore Scaffolding

- Offshore Abseiling

- Painting Inspection

- Trained and approved of qualified Blasters/Painters.

Now as acknowledgement of the skill and expertise, client is offering opportunities for onshore services as well.

Why Mashhor Offshore Painting (MOPS)

- Single minded concentration on blasting & painting & related services as one stop solution provider for quality services.

- Special focus on Bruneisation development through local manpower skills

- Pool of qualified & experienced workforce including local abseilers, supervisors and paint inspectors

- Emphasis on highest quality & safety on in every aspect of the business

Now as acknowledgement of the skill and expertise, clients are offering opportunities for onshore services as well.

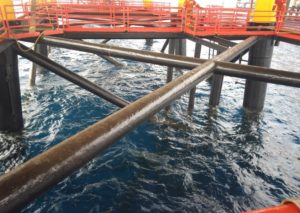

BSP offshore platform – CPLQ 7 BSP Onshore Facilities – Manifold 13

Vapor Abrasive Blast Cleaning (VAB) –

This method is used as an alternative surface preparation method of steel surface prior to coating application as opposed to the conventional dry abrasive blast cleaning for offshore platforms because of its many advantages over the latter.

Vapor Abrasive Blasting is a surface preparation method where medium of blasting is wet, as opposed to dry blasting medium in conventional dry abrasive blasting.

The key to vapor blasting is that the finish is produced through flow of water borne abrasive, giving a finer finish due to the flushing action of the water. No media is saturated into the component, nor is there any dust created by the break-up of media, unlike dry blasting where the finish is produced by sheer force of media impact.

A specially designed pump agitates water and media into slurry, and pumps it to the blast gun. At the same time this slurry is pumped at approximately 30 psi to a maximum of 140 psi to the nozzle, and air is introduced at the blast gun to accelerate the slurry and its cleaning effect on impact.

Vapor Abrasive Blast Cleaning method is especially beneficial when used on offshore platforms where sensitive equipment such as generators and air suction are located and also at sensitive area where there is expectation of minimal dust and hot work. Reduced airborne particles during blasting eliminate the chance of dust being ingested into turbines, air suction etc. It also keeps the work site and neighboring areas clean and allow others activities to be carried out concurrently with blasting in the vicinity. MOPS is the first contractor to use VAB as a means of surface preparation for steel on BSP facilities